Discharge bars and power supplies are used which are able to discharge to a minimum residual charge at high web speeds.

For the detailed solution description of this application or a consultation on your application problem, click here:

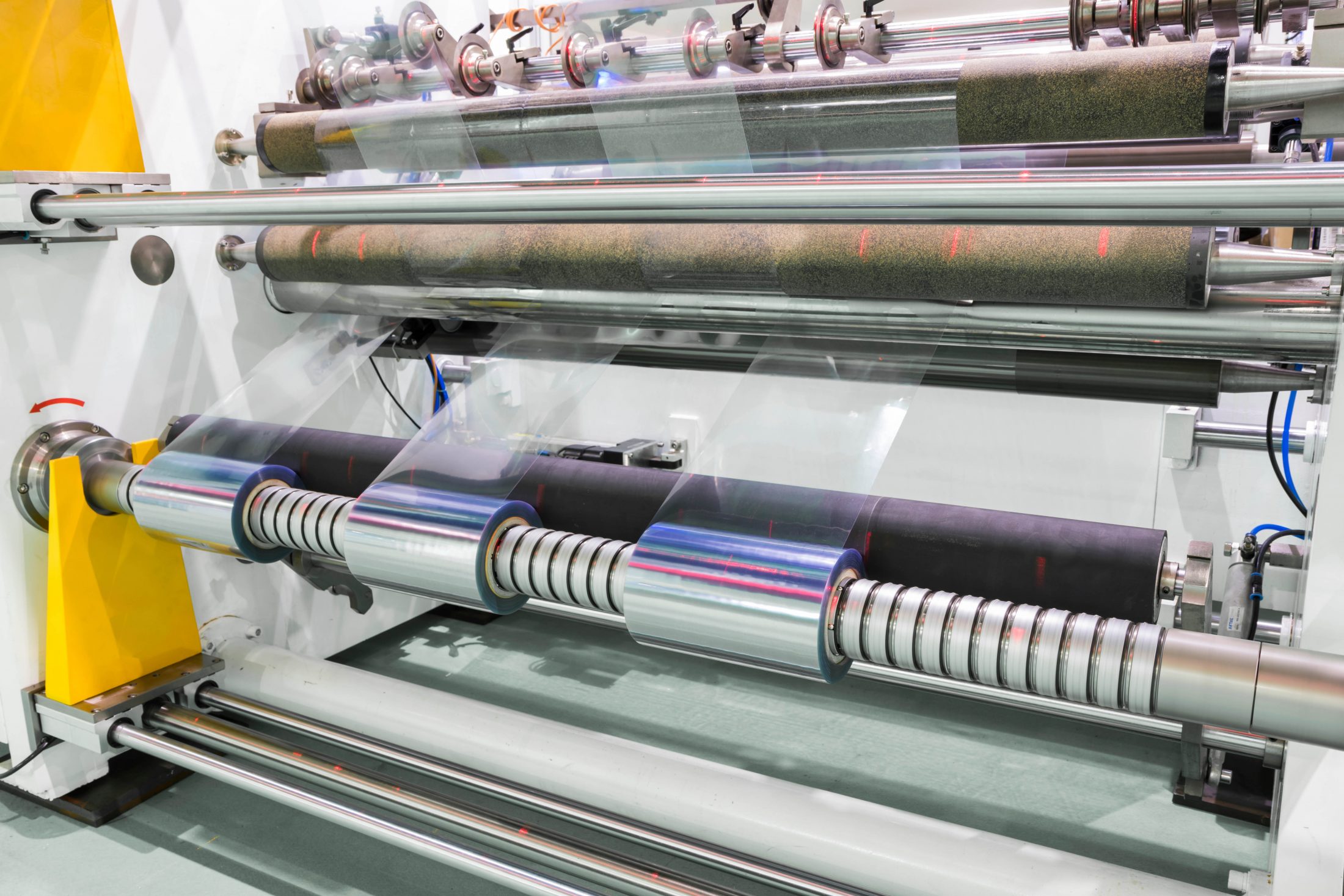

On the slitter rewinder, a rotogravure-printed plastic film, e.g. OPP, is cut lengthwise into several panels. The individual panels are as wide as a subsequent packaging machine. However, the individual panels are transported to another packaging plant. The slitter rewinder is the last machine before this film goes to the packaging plant. To avoid complaints due to electrostatically charged film, the film must be discharged as best as possible in the winder. As proof, the residual charge is measured and recorded on each film.

Discharge bars and power supplies are used which are able to discharge to a minimum residual charge at high web speeds.

For the detailed solution description of this application or a consultation on your application problem, click here:

The following Eltex products have been installed and tested on site by our experts. If you would like to learn more or have any questions, please do not hesitate to contact us.

The high-performance discharge power supply POWER IONIZER impresses with its flexibility. The simple operation, the LED display for visualization of the current values and the integrated function and malfunction monitoring characterize the power supply unit. The POWER IONIZER can be operated with the Eltex AC discharging bars, ion blower nozzles and ion blower pistols. Lowest residual charges can be achieved by different adjustable parameters. Operation is possible as single unit or in a network. Protocol/device description files of the fieldbus interfaces for integration into the machine control: Information fieldbus integration

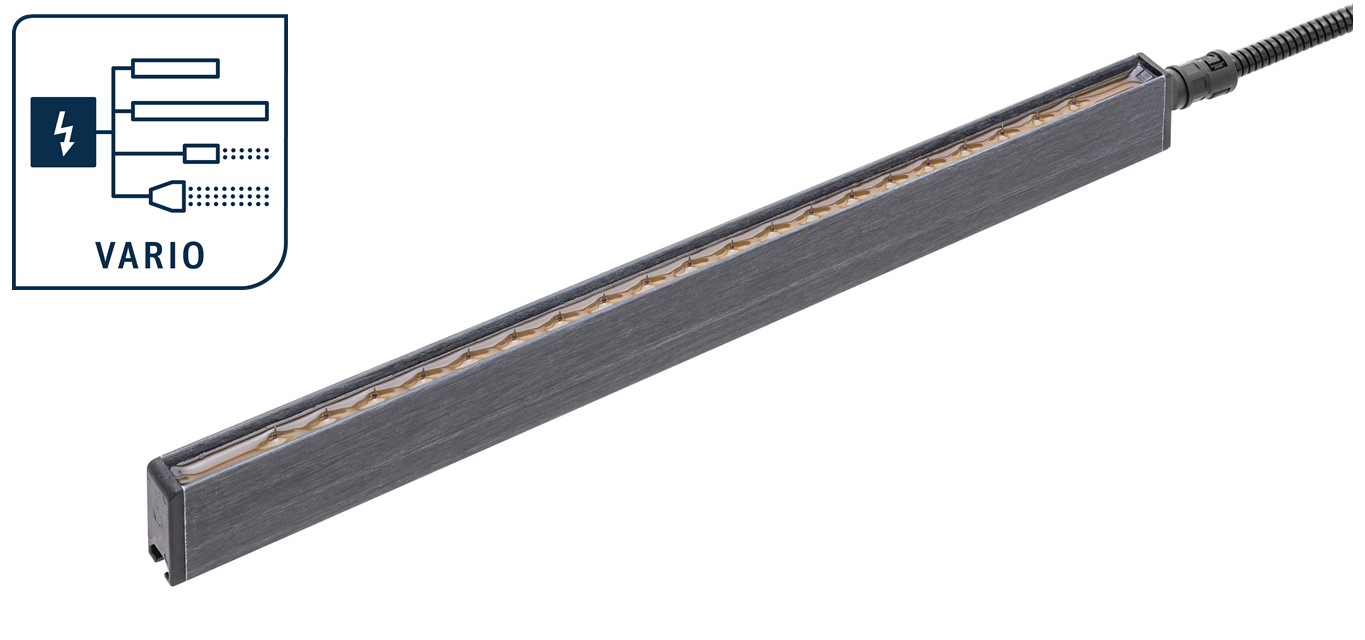

The robust all-rounder bar The VARIO discharge bar blueBAR R50 creates a significantly higher active discharge capacity than most discharge techniques. The isolated ground conductor enhances the E-field at the active tips, contributing to increased production and velocity of charge carriers. Thus, significantly more positive ions and free negative electrons are available than with conventional bars. At the same time, the bars have a high passive discharge capacity. The resistance-decoupled tips ensure good discharge performance and make the bar absolutely short-circuit and touch-proof.