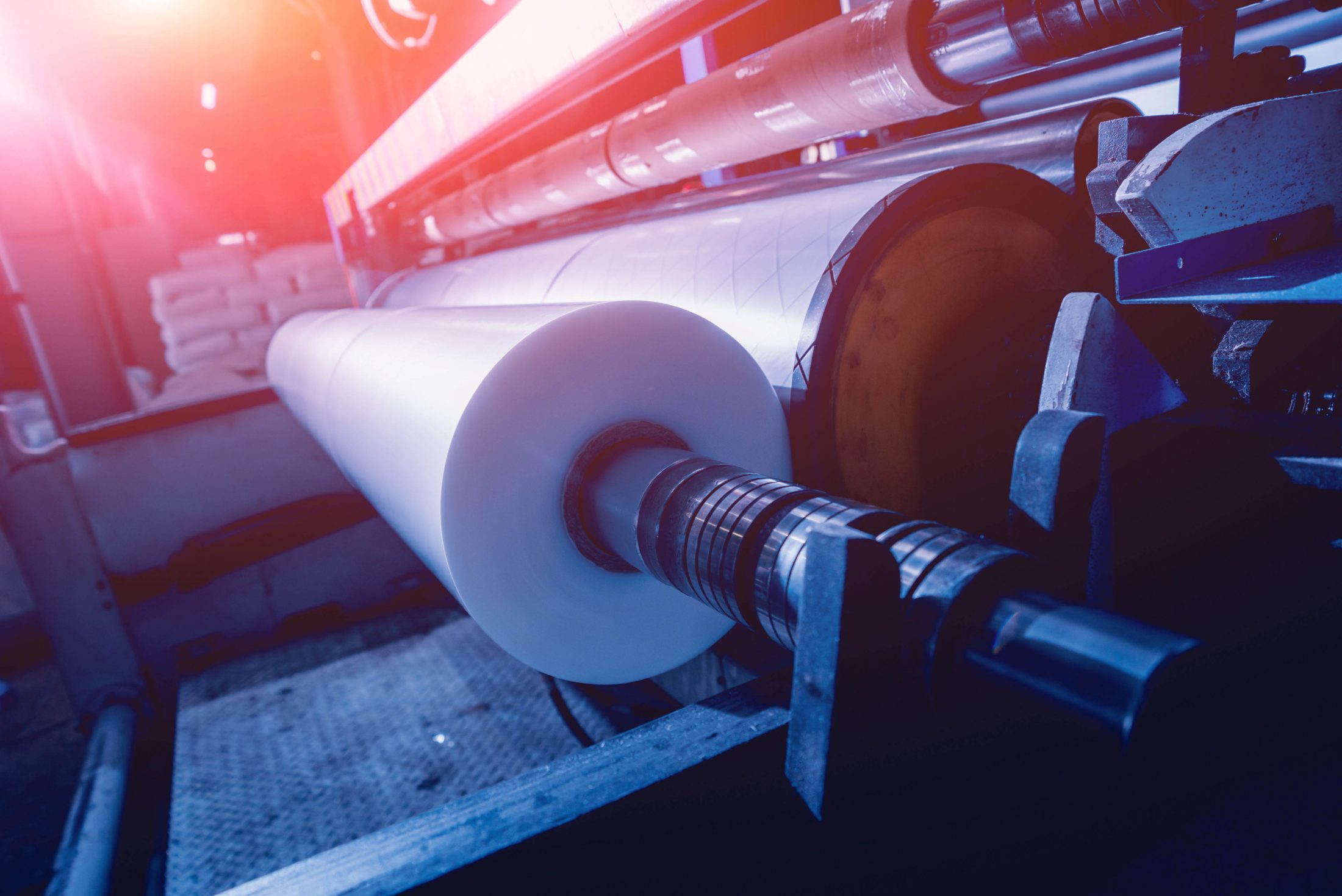

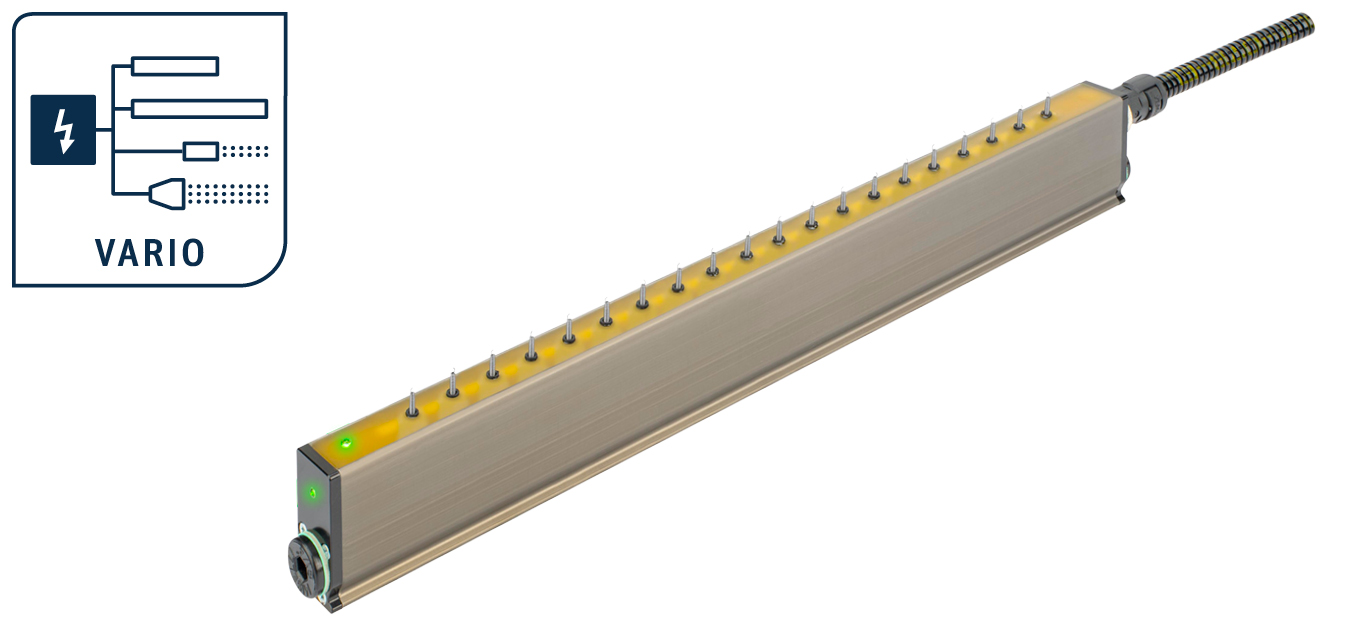

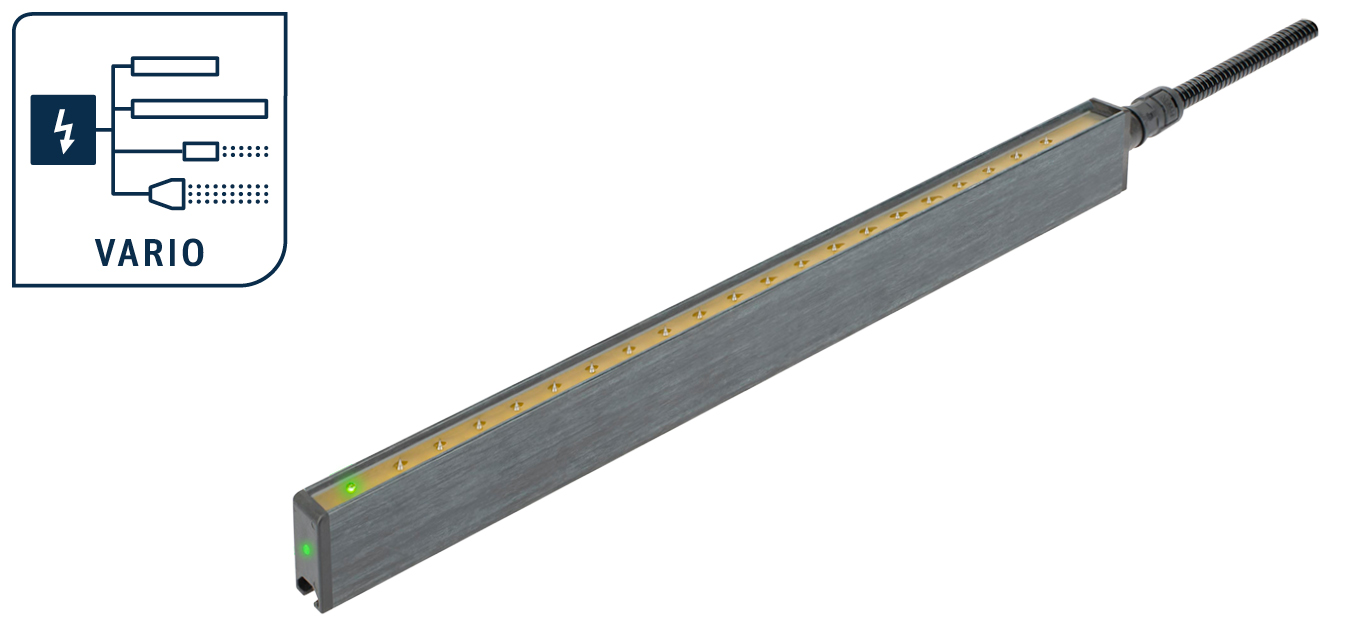

The highly charged plastic wrap is reliably discharged with unique ionization bars. The bars can be installed at a large distance from the winding surface.

For the detailed solution description of this application or a consultation on your application problem, click here: