The electrostatically charged materials must be discharged without contact using ionizers suitable for the application. In order to successfully discharge the product, it is necessary to install the ionizers in a physically ideal position.

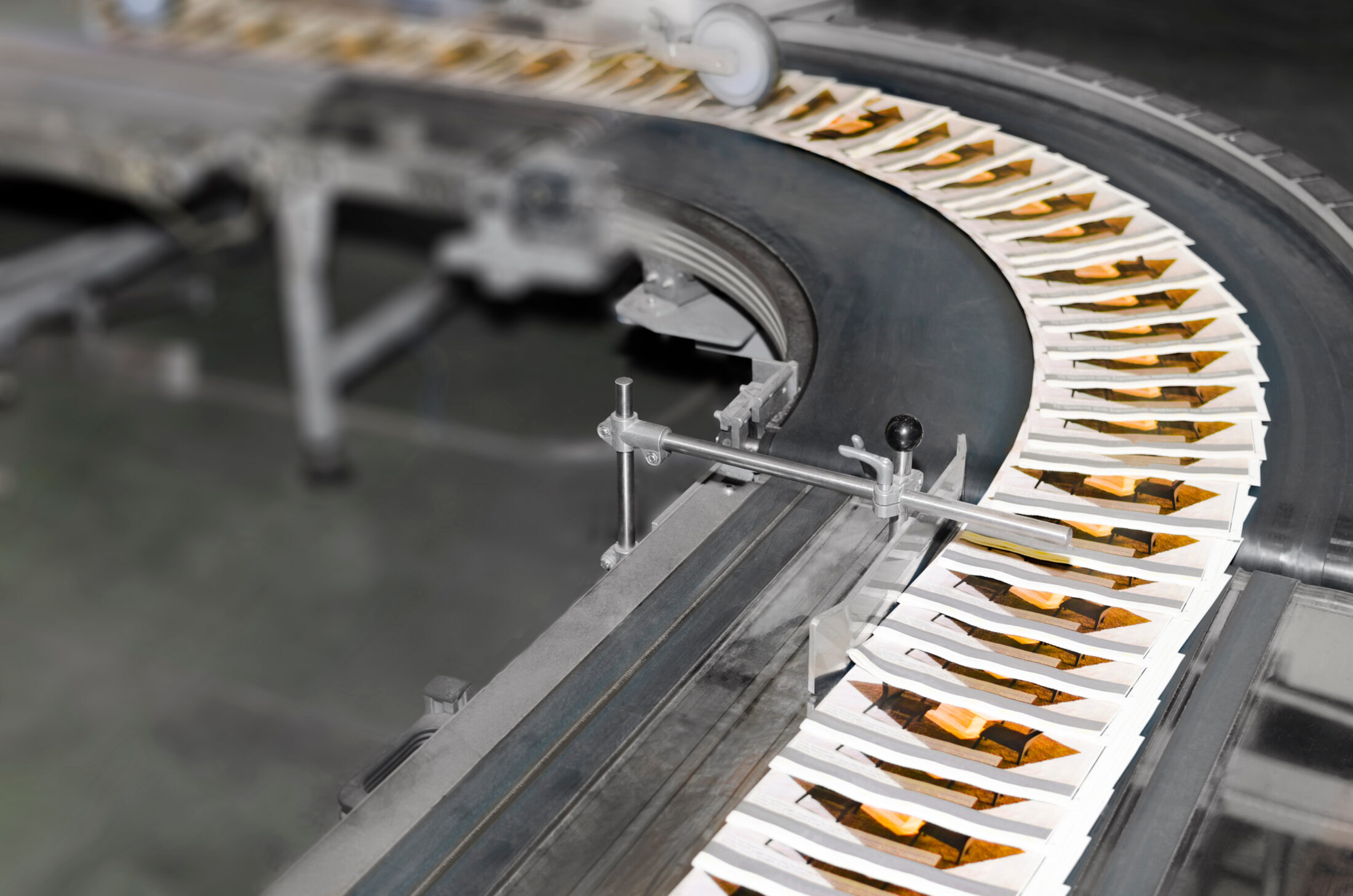

Electrostatic discharge on a screen printing transfer machine

How does the screen printing transfer work?

In screen printing transfer, the screen print is not printed directly on the substrate, but beforehand on a special transfer paper. Once the motif is printed on the transfer paper, it is sprinkled with a fine adhesive granulate and then dried for several minutes through a drying channel. The excess granules lying next to the ink on the transfer paper are to be blown away in the machine outlet with a blower.

How can excess granules be safely removed?

Contact and separation of doctor blade, screen and substrate can cause all materials involved to become electrostatically charged. The granules may also already be electrostatically charged on delContact and separation of doctor blade, screen and substrate can cause all materials involved to become electrostatically charged. The granules may also already be electrostatically charged on delivery. The granules also adhere next to the printed areas of the transfer paper due to the electrostatic charge of the materials involved in the printing process. The excess granules cannot be completely removed with a conventional blower. This results in customer complaints due to quality defects.

Our solution

POWER IONIZER

The high-performance discharge power supply POWER IONIZER impresses with its flexibility. The simple operation, the LED display for visualization of the current values and the integrated function and malfunction monitoring characterize the power supply unit. The POWER IONIZER can be operated with the Eltex AC discharging bars, ion blower nozzles and ion blower pistols. Lowest residual charges can be achieved by different adjustable parameters. Operation is possible as single unit or in a network. Protocol/device description files of the fieldbus interfaces for integration into the machine control: Information fieldbus integration

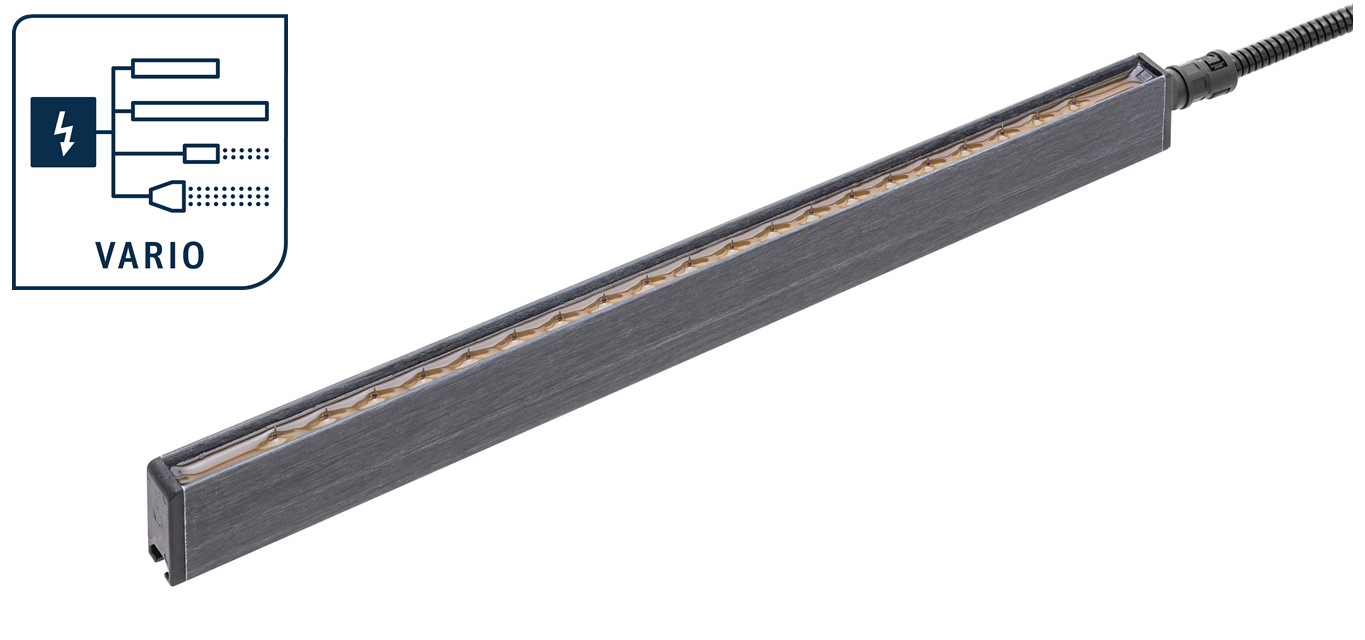

blueBAR R50

The robust all-rounder bar The VARIO discharge bar blueBAR R50 creates a significantly higher active discharge capacity than most discharge techniques. The isolated ground conductor enhances the E-field at the active tips, contributing to increased production and velocity of charge carriers. Thus, significantly more positive ions and free negative electrons are available than with conventional bars. At the same time, the bars have a high passive discharge capacity. The resistance-decoupled tips ensure good discharge performance and make the bar absolutely short-circuit and touch-proof.