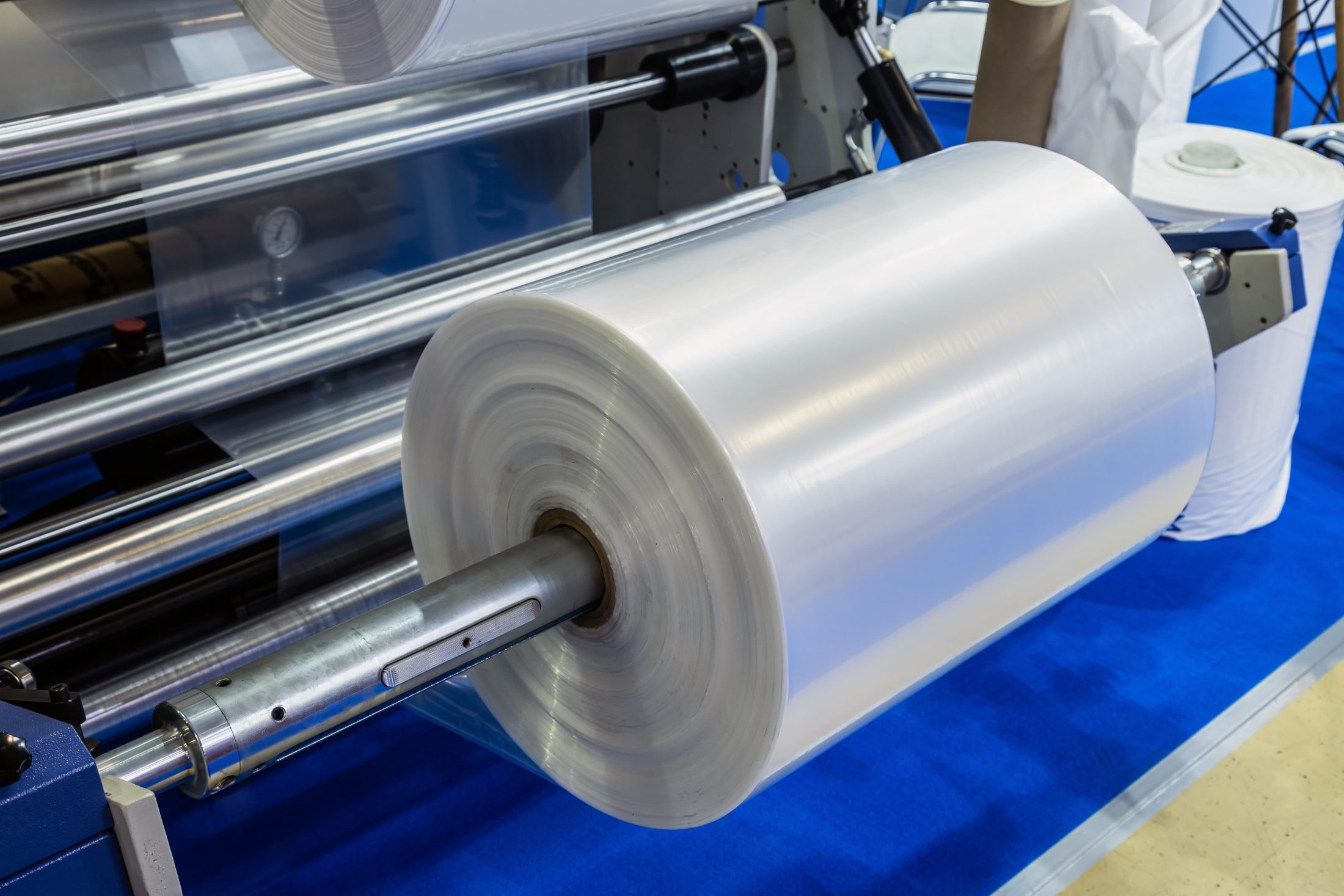

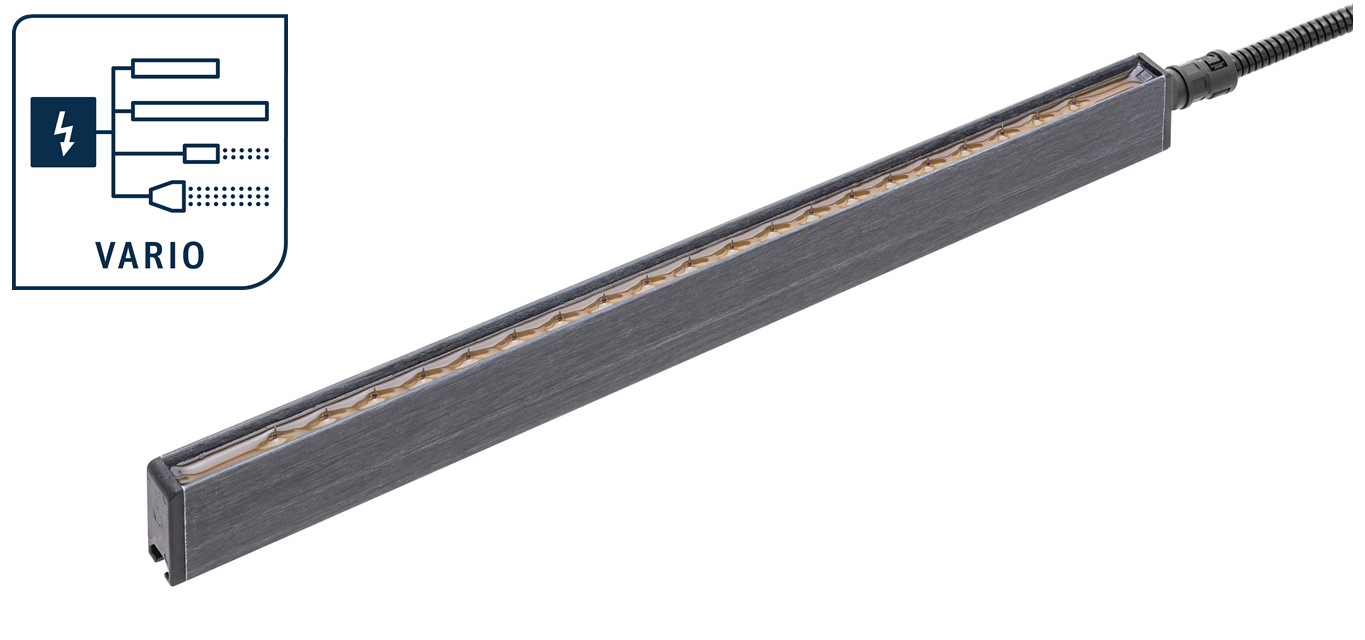

Two different electrode types with different operating principles were used in order to be able to discharge ideally with all unwinding variants.

For the detailed solution description of this application or a consultation on your application problem, click here: