The problem can be solved by a combination of suitable measurement technology and charge compensation.

Electrostatic discharge of charge double layers for films

Gravure printing press in flexible packaging / production of flat films

During the production of high-resistance plastic films or their printing in gravure printing presses, in particular when using an electrostatic printing assist, the formation of charge double layers on the film is possible.

This results in electrostatic charges that are difficult to discharge.

Charge double layers, which in extreme cases have the same charge with different sign on both sides of the film, cannot generally be eliminated by conventional discharge with ionizers. The negative effects of the charge double layer occur mainly during winding of the film, but also during unwinding of the film in the succeeding machines. Strong electrostatic discharges can occur there. In packaging machines in which such films are processed, the film adheres to machine parts and thus causes transport problems.

Our solution

Which Eltex components are used?

POWER CHARGER

The POWER CHARGER units cover various performance stages and charging applications. They can be operated either with a supply voltage of 24 V DC or a line voltage in the range of 85 V – 264 V AC. The output voltage is 75 or 150 watts. A membrane keyboard or an optionally available, integrated touch panel is used to control the generators. POWER CHARGER units can be operated using analog operation or via digital fieldbus interfaces. At the market launch, a control system that uses CANopen and ModbusTCP are available. The modular system is only prepared for integrating other fieldbus standards. Protocol/device description files of the fieldbus interfaces for integration into the machine control: Information on fieldbus integration

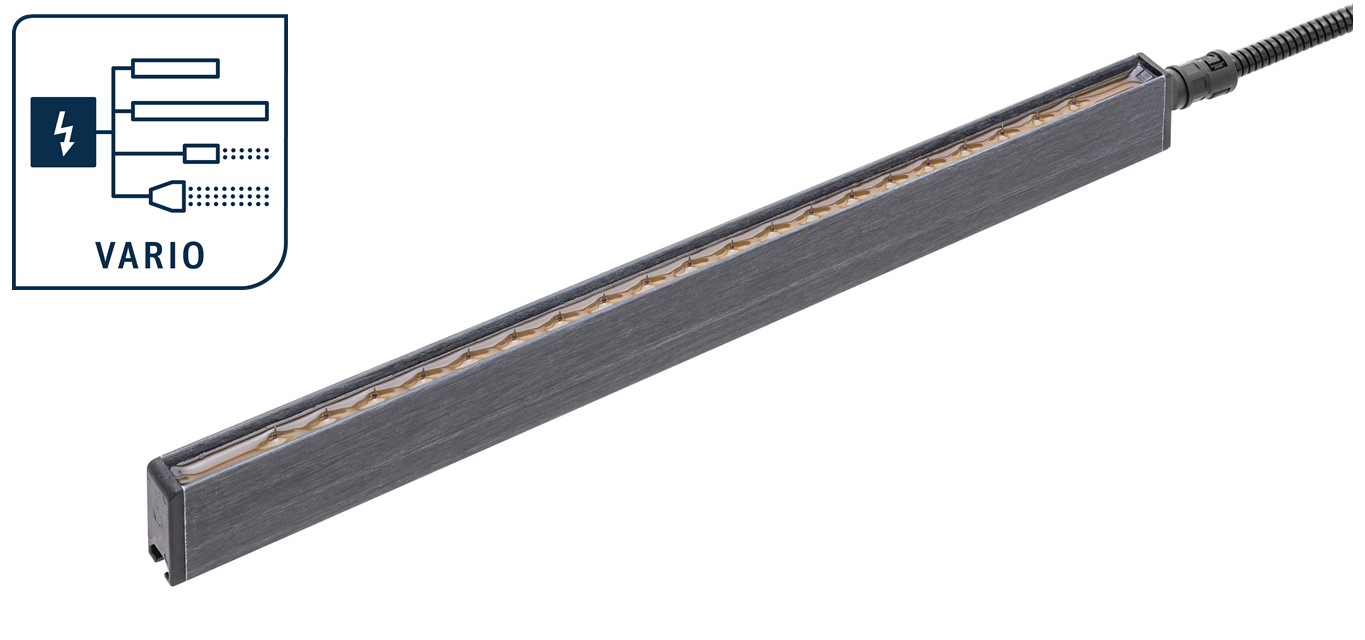

blueBAR R50

The robust all-rounder bar The VARIO discharge bar blueBAR R50 creates a significantly higher active discharge capacity than most discharge techniques. The isolated ground conductor enhances the E-field at the active tips, contributing to increased production and velocity of charge carriers. Thus, significantly more positive ions and free negative electrons are available than with conventional bars. At the same time, the bars have a high passive discharge capacity. The resistance-decoupled tips ensure good discharge performance and make the bar absolutely short-circuit and touch-proof.

IONIZER ES51

The robust all-rounder with a large power input The VARIO IONIZER ES51 has 5 connections and works with proven Eltex technology. On the top side there is a LED display for the function and fault message. The device also has an analog interface. For a good ion balance, the device is available with and without parameter diode.

R130

Heavy-duty precision bar for supply voltages up to 60 kV. The charge and field distribution have been substantially improved by the optimized arrangement of the individual bars. Separate current-limited tips prevent an increase in air ionization and high-energy brush discharges.