An injection molding machine is a machine that produces plastic parts from plastic in granular form. For this purpose, the required molding compound is prepared in the injection unit and injected into a die, which represents a negative mold (cavity) of the desired plastic part. Depending on the process used (thermoplastic injection molding, thermoset injection molding or elastomer injection molding), various components of the machine are heated or tempered. Injection molding machines generally consist of two parts: The injection unit, which prepares the raw material and injects it into the mold under pressure, and the clamping unit, which receives the mold and opens and closes it.

Continue reading

Various plastic parts, the circuit board and LED modules are put together on an assembly line for different car headlights.

Continue reading

An injection moulding machine is a machine that produces plastic parts from plastic granulate. For this process, the required molding compound is prepared in the injection unit and injected into a die, which represents a negative mold (cavity) of the plastic part. Depending on the process used (thermoplastic injection molding, thermoset injection molding or the elastomer injection molding), various components of the machine are heated or tempered. In this application, the injection moulding machine is located in a clean room. Medical plastic parts are produced.

Continue reading

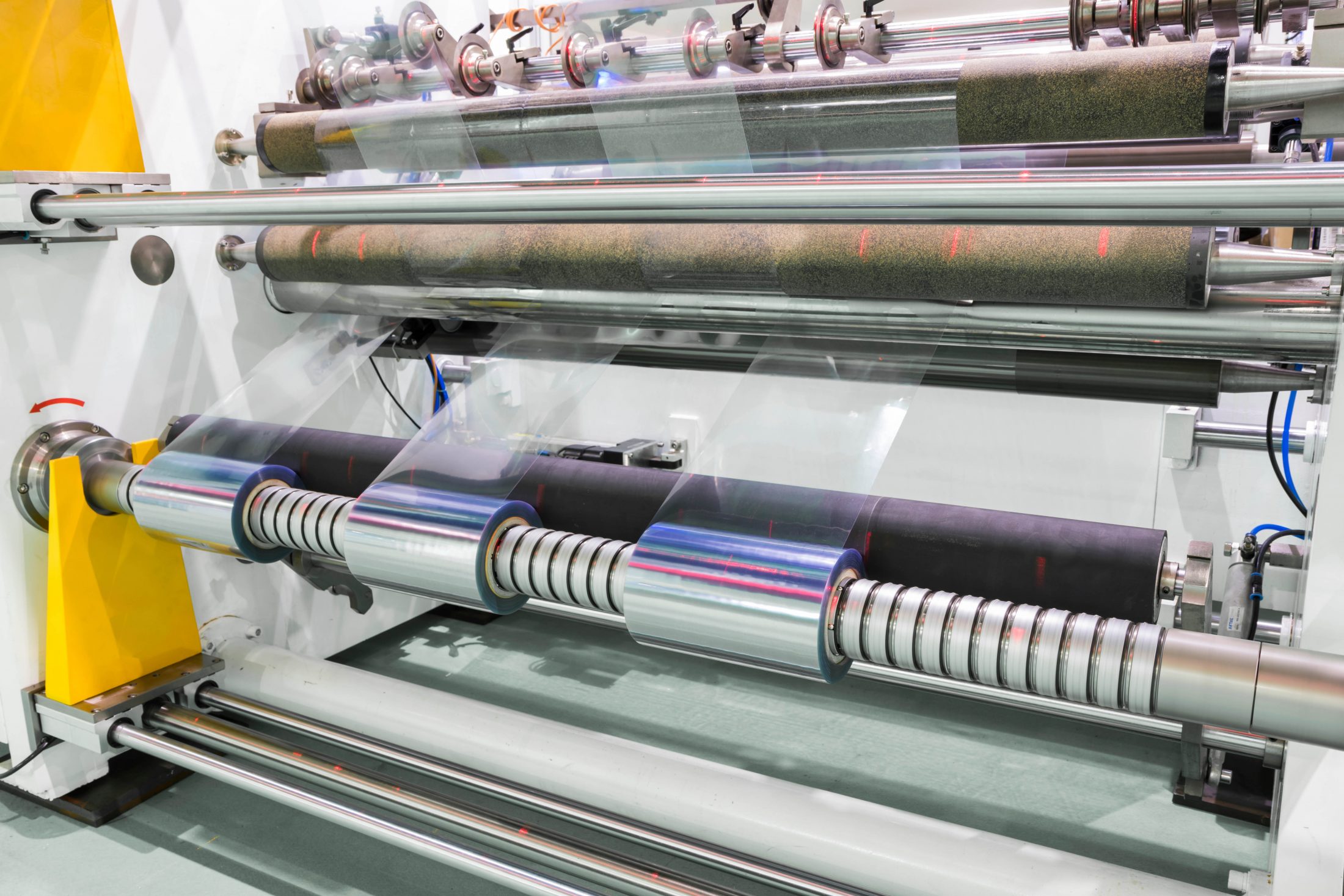

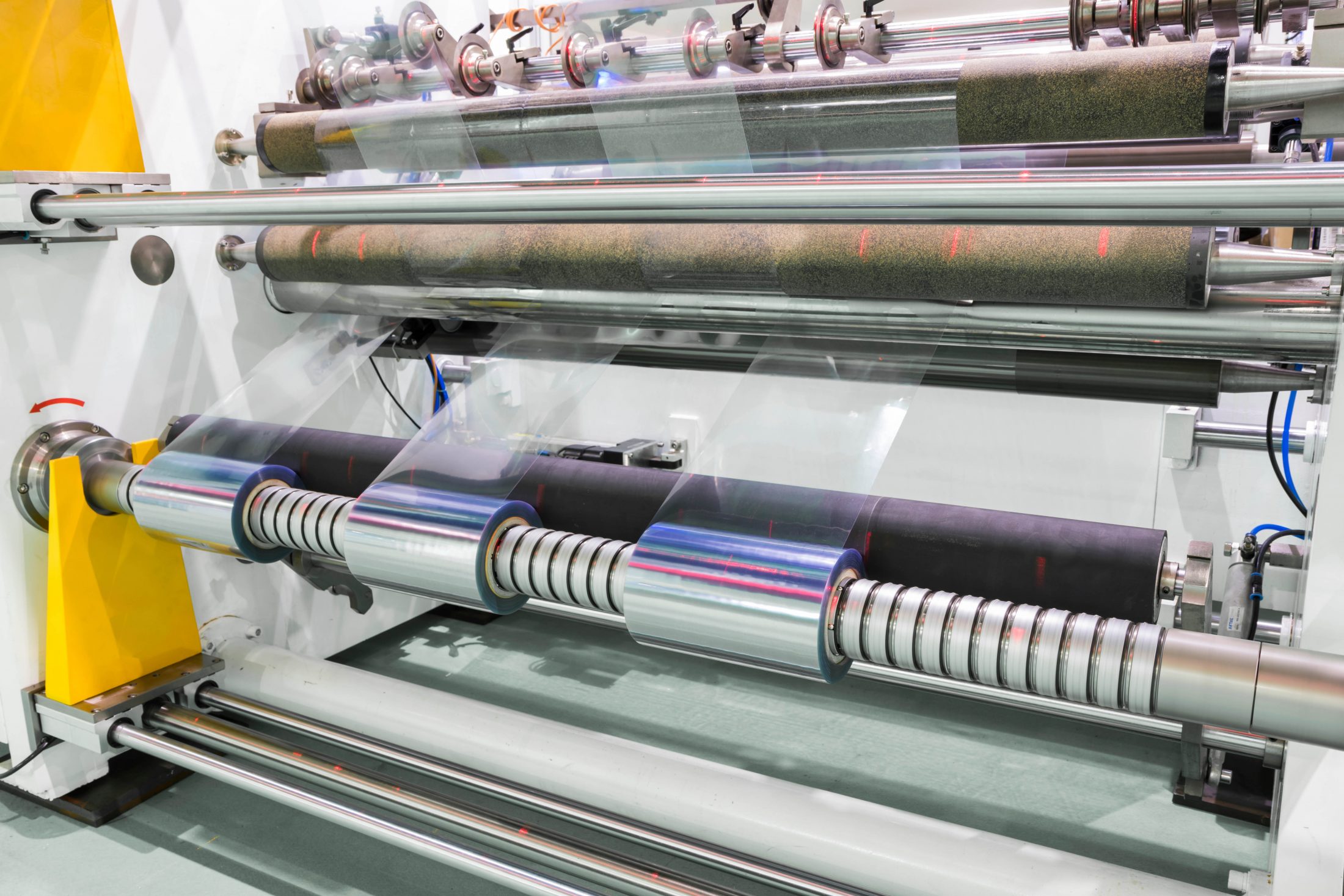

A plastic film printed in gravure, e.g. OPP, is cut lengthwise into several batches on the slitter rewinder. The individual batches are as wide as a downstream packaging machine. However, these are transported to another packaging plant. The winder is the last machine before this film goes to the packaging plant. To avoid complaints due to electrostatically charged film, the film must be discharged in the best possible way in the slitter rewinder. As proof, the residual charge on each film is measured and recorded.

Continue reading

Suction pipes are used, for example, to transport punching or cutting waste from a printing press via a pipe system to a waste disposal facility. The same applies to edge trim suction in plastic film production. The material waste is compressed in the stationary compactor and then transported to the transport container. The full container is transported away by truck.

Continue reading

A shrink sleeve film is unwound on a cross-cutting machine and then cross-cut. The cross-cut films are placed in a shed on a conveyor belt. Afterwards, small film packets are formed from the scale by hand. The packets are placed in a box.

Continue reading

The system cleans plastic parts for automotive headlights. The machine operators place plastic parts from an injection molding machine into a rotating holder of a cleaning module. The cleaning module rotates the parts in front of the cleaning system. Before the car headlights are assembled, the electrostatically charged plastic parts are discharged and cleaned.

Continue reading

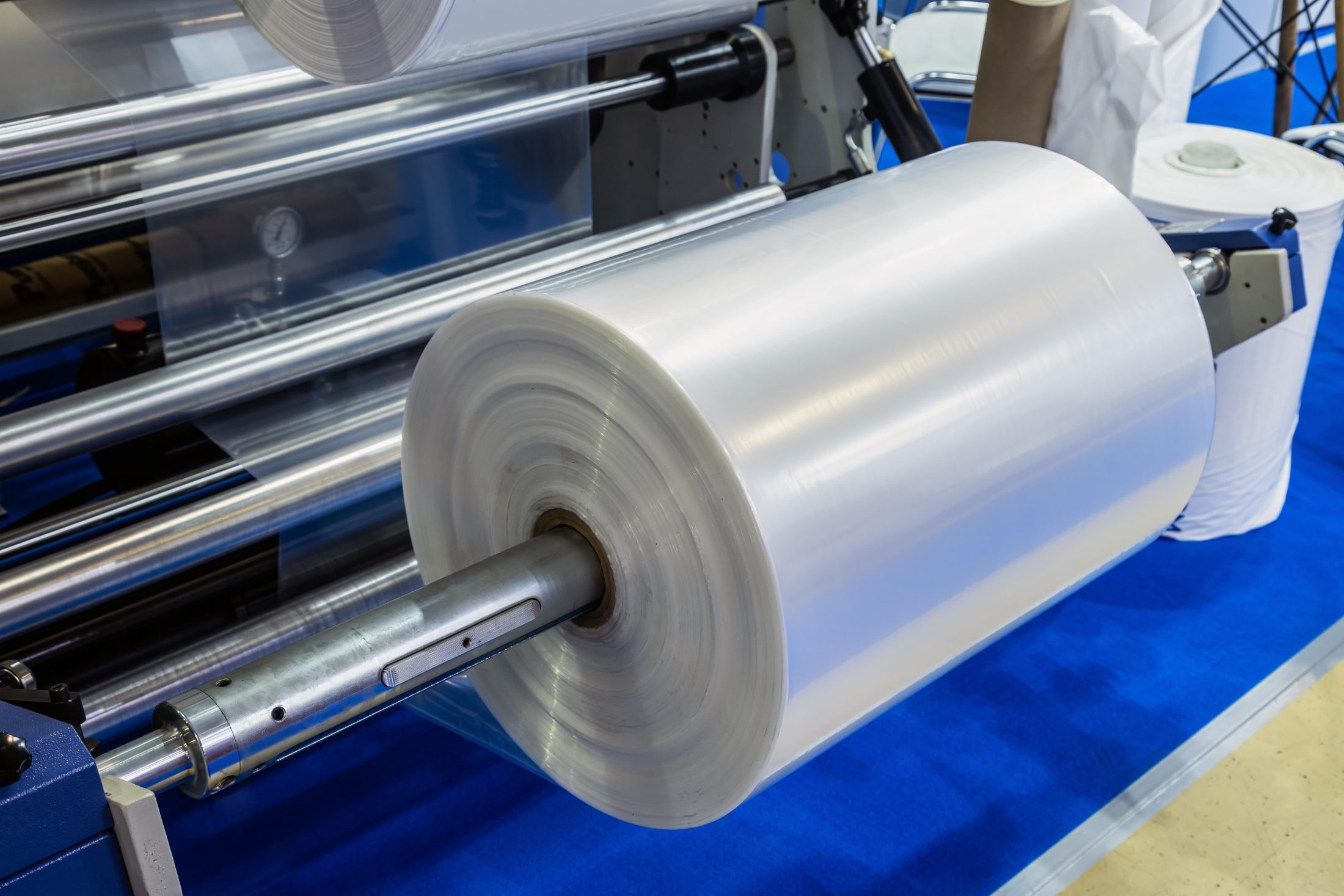

On a turret winder downstream of a film extrusion line, the film is cut lengthwise onto several panels and wound up. When the reel is full, an automatic reel change takes place. During a winding change, the film must continue to run and the next film winding must be started properly and without creases.

Continue reading

On a foil stamping machine, a plastic foil is unwound at two unwinding stations and then passes on to the stamping unit. The film can be unwound at both unwinding stations from the top or bottom side.

Continue reading

In the production of a container, 4 drums filled with different substances are placed individually next to each other on a pallet. The substances are sucked in with a suction nozzle and transported further via pipes. During the suction process, the substances and the barrel are electrostatically charged. The drums must therefore be grounded and the ground connection monitored. The application is located in the EX-area!

Continue reading

With a grinding material suction system, there are problems with electrostatically charged grinding material. The regrind material is sucked in via a hose with an outer diameter of approx. 72 mm and is electrostatically charged in such a way that the material partially adheres to the metal funnel and does not fall down. As a result, the entire system becomes clogged and cleaning-related downtimes occur.

Continue reading

A blown film is a film made of a thermoplastic material, which is produced with the help of a special blown film extrusion line. The way it works is that molten plastic is blown out of a ring-shaped nozzle with the help of air. The solidified tube is folded by a pair of rollers at a height of 10-20 metres. At the end of the line, the film is cut lengthwise and usually wound separately on two winders. Typical machine speeds are around 10-20 m/min. These continuous films are mainly used for packaging food, medical products or in the pharmaceutical sector.

Continue reading

On web offset presses, paper ribbons are cut lengthwise and then run through the press, one on top of the other, to the former fold.

Continue reading

After the web offset press, the products are transferred to an inline finishing system for the direct mail market.

Continue reading

When supplements are being inserted, e.g. in an advertising brochure, these copies are first opened by the postpress machine. Ideally, the supplement must be inserted between two defined pages.

Continue reading

On a gathering machine, the various pages of a magazine are gathered via a transport chain and then wire-stitched in the saddle stitcher. There is often a requirement for a small saddle stitcher to be placed over the title, e.g. exactly in the middle.

Continue reading

Adhesive-bound print products fall via a conveyor belt into a collecting chute where they form a stack. From there, the copies are fed to a three-knife trimmer which trims the print products at three edges.

Continue reading

Printed sheets always have a larger volume at the waistband than at the open side due to the fold. In order to deliver a stable package of printed sheets from the presses, the sheets must be interleaved crosswise. The sheets run in a shingled manner or individually into the receiving shaft of the compensating stacker. Depending on the thickness of the printed product, a certain number of sheets are piled one on top of the other, then the pile is rotated by 180°.

Continue reading

A palletizer in a print finishing plant removes a pile of printed products from a belt and places the pile on a pallet. The piles are pushed open in front of the palletizer and enter a rotating device, in which the piles are optimized for the palletizer. When a row is full, the gripper moves under the row of stacks and places it on the pallet by tilting it slightly.

Continue reading

In screen printing transfer, the screen print is not printed directly on the substrate, but beforehand on a special transfer paper. Once the motif is printed on the transfer paper, it is sprinkled with a fine adhesive granulate and then dried for several minutes through a drying channel. The excess granules lying next to the ink on the transfer paper are to be blown away in the machine outlet with a blower.

Continue reading

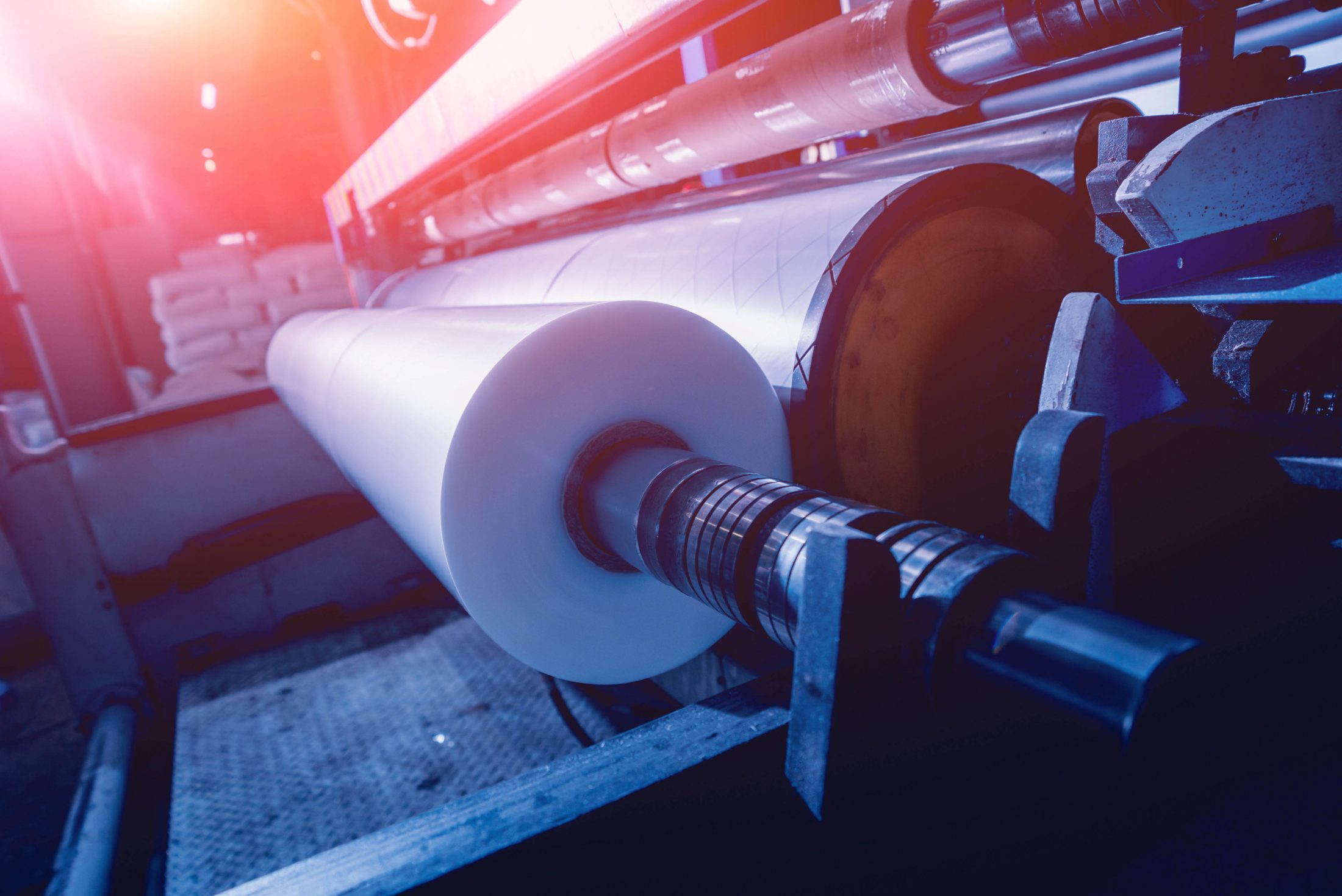

During the production of high-resistance plastic films or their printing in gravure printing presses, in particular when using an electrostatic printing assist, the formation of charge double layers on the film is possible.

Continue reading

A plastic film printed in gravure or in flexo printing is controlled on an inspection machine with regard to its print quality. Instead of the inspection machine, however, the printing press can also be followed by a slitter rewinder or a coating machine. In all cases, the plastic film is unwound at the unwinder.

Continue reading

Gathering machines consist of 15 - 25 individual stations (feeders). The individual products, which in the end make up a bound booklet, are conveyed via the feeders onto a carrier chain. Individual products can consist of 1 - 10 sheets. A cross accelerator then gives the product the required chain speed.

Continue reading

Gathering machines are used to gather individual sheets in the desired arrangement. Machines with up to 30 stations are built. A gripper arm with suction nubs takes the single sheet from the top and places it on the transport chain. The stacks are fanned out from the front with compressed air using an aluminum perforated bar to prevent sticking, so that multiple sheets are not taken out. This works quite well with paper, with films there are problems due to higher electrostatic charge!

Continue reading

The machine consists of an unwinder, a split & merge module and a cross cutter. After unwinding the digitally printed paper, the split & merge module is used. The paper web is fed over a plow fold and folded in such a way that the original web width is halved. This allows 2 paper thicknesses to be fed into the cross cutter to produce products such as 4-sided letters. Papers from 40 to 250 gsm are processed.

Continue reading

In the production of print products, e.g. magazines, using web offset or gravure printing, the finished magazines are usually stacked on top of each other in a compensating stacker and then packaged in a packaging machine. After the compensating stacker, the stacked printed products are transported to the packaging machine via conveyor belts. Usually, the complete piles are electrostatically charged so that the individual printed products are attracted to each other. As a result, a pile can usually be transported in a stable manner.

Continue reading

Solvent-based inks or other flammable liquids are used in gravure printing presses or laminating machines. The flammable liquids are stored, transferred, sampled or even mixed in metallic, non-fixed containers directly at the machine.

Continue reading

Electrically conductive drums are filled or emptied with a solvent-containing liquid.

Continue reading

Trucks or even kettle scales are filled or emptied with liquid containing solvents in hazardous areas.

Continue reading

On a Xeikon digital press, the paper is processed from the roll, preheated, printed and burned in.

Continue reading

The small printer is used to print small quantities, mainly promotional items, pens, buttons, etc.

Continue reading

On a gravure press for flexible packaging there are many printing units with barrels and containers of solvent-based ink. Solvent-based ink is pumped or stirred into these containers. Mobile pump or agitator scales are available for this purpose. Larger containers are moved directly to the printing unit concerned. All conductive mobile containers must be grounded with grounding tongs. For cost reasons, the tongs used usually work passively.

Continue reading

The cleaning of floors in exhibition halls, airports, etc. is increasingly carried out dry, with plastic brushes rotating to clean the floor and the operator seated to control the vehicle.

Continue reading

![]()

A suction dredger is a truck for suction and dredging of solid and liquid materials.

Continue reading

Large PMMA sheets, also known as Perspex, Plexiglas or acrylic, are used in camper van construction. The PMMA sheets are painted with a solvent-based paint in the hazardous area.

Continue reading

The car seats arrive to the assembly station wrapped in a foil and are unpacked there. During the assembly of the car seats, the foam is covered with integrated and insulated steel linkage, with the textile cover. This work is done manually.

Continue reading