We help companies use electrostatic control to optimize industrial processes, increase productivity, efficiency and production quality, and minimize hazards and risks.

Optimize your industrial processes by using electrostatics

Discharging of automotive lights on a mounting module

Various plastic parts, the circuit board and LED modules are put together on an assembly line for different car headlights.

Discharging of shrink sleeve films

A shrink sleeve film is unwound on a cross-cutting machine and then cross-cut. The cross-cut films are placed in a shed on a conveyor belt. Afterwards, small film packets are formed from the scale by hand. The packets are placed in a box.

Grinding material suction

With a grinding material suction system, there are problems with electrostatically charged grinding material. The regrind material is sucked in via a hose with an outer diameter of approx. 72 mm and is electrostatically charged in such a way that the material partially adheres to the metal funnel and does not fall down. As a result, the entire system becomes clogged and cleaning-related downtimes occur.

Effective discharging of small injection molded parts in the container

An injection moulding machine is a machine that produces plastic parts from plastic granulate. For this process, the required molding compound is prepared in the injection unit and injected into a die, which represents a negative mold (cavity) of the plastic part. Depending on the process used (thermoplastic injection molding, thermoset injection molding or the elastomer injection molding), various components of the machine are heated or tempered. In this application, the injection moulding machine is located in a clean room. Medical plastic parts are produced.

All about Eltex

Visit us at the productronica 2025 – The world's leading trade fair for the development and production of electronics.

Period: 18.–21. November 2025 | Messe München

Booth A1.553

Visit us at K 2025 – the leading international plastics trade fair.

Period: 08.–15. October 2025 | Messe Düsseldorf

Hall 10 Booth F23

PRO IONIZER EX ES61/E

The PRO IONIZER EX ES61/E discharging power supply ensures active discharge of electrostatic charges in the Ex area. With the new performance control, the power and status of any connected discharging bar an be monitored separately. Adjustable process parameters and fieldbus integration are easily possible. Click here for more information! Protocol/device description files of the fieldbus interfaces for integration into the machine control: Information on fieldbus integration

How Smart Electrostatic Grounding Helps you Avoid Risks

Smart grounding: avoid risks with electrostatic grounding.

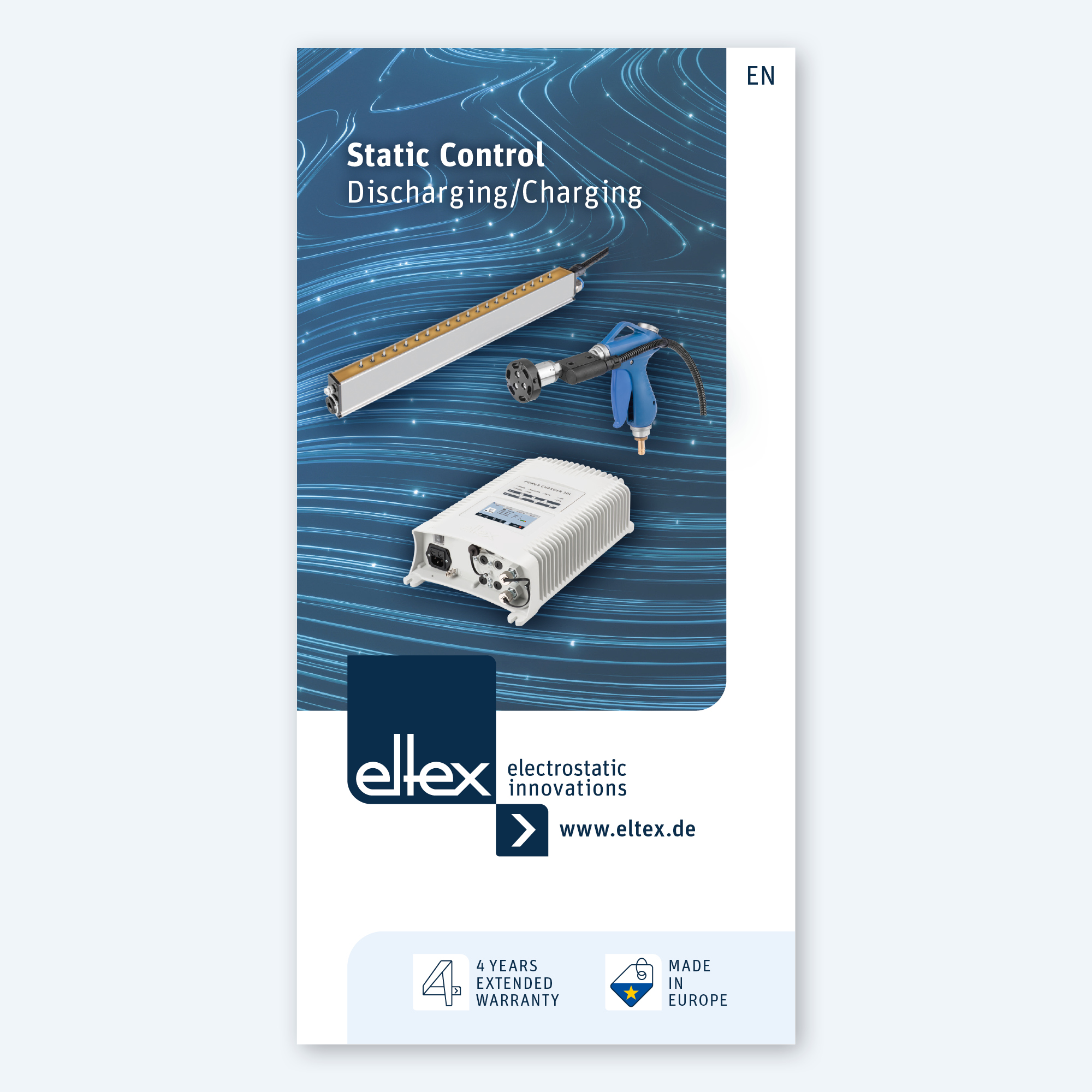

Overview brochure

Discharging / Charging

The Static Control products as PDF download or printed on request

Overview brochure

Electrostatic grounding

The Grounding products as PDF download or printed on request

Electrostatics and industry

During the processing and finishing of materials which are insulating in one form or another (e.g. paper, textiles, glass, wood, chemicals, plastics), electrostatic charges are inevitable. Charges develop when materials are processed and rub against one another, or when objects formerly in contact are suddenly separated, or when materials are joined, bonded, glued or welded. The problem lies not only with the materials, but with the energy used to move these materials, whether they are solids, liquid, gases or powders. The higher the speed is, the more trouble the electrostatic charge can cause.

Charging – Discharging

Uncontrolled electrostatic charges are always undesirable and can impede the efficiency of manufacturing processes. On the other hand, controlled electrostatic charges – purposely applied – improve manufacturing efficiency by using electrostatic properties to accomplish something beneficial in the process.

Electrostatic systems

Whether too small to see or a bolt of lightning, the spark is a typical phenomenon that accompanies electrostatic discharges. Eltex has the expertise and the engineering skills to measure, control, eliminate and utilize these elemental forces.

Are you looking for technical solutions or do you have questions about our product portfolio?

We help companies use electrostatic control to optimize industrial processes, increase productivity, efficiency and production quality, and eliminate hazards and risks.

Values that are lived create trust.

Eltex Elektrostatik GmbH in Weil am Rhein, founded in 1953, is the world's leading manufacturer of electrostatic systems. In 70 years of successful company history, the intelligent and innovative solutions have established themselves in numerous industrial sectors. An international sales network with 50 representatives ensures a worldwide presence.